Who We Help

Foreign material contamination and quality issues can happen to anyone who manufactures product, no matter what that product might be. We’re able to provide our quick, thorough and accurate X-ray inspection services and Flexible Solutions to customers spanning all industries in the food and beverage manufacturing space.

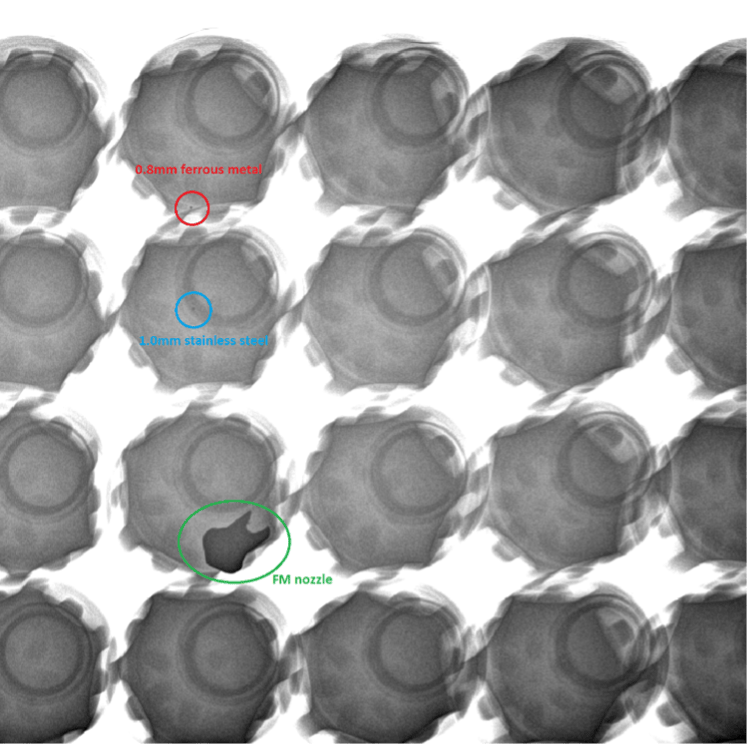

X-Ray Inspection Services

If you’re dealing with on-hold product due to foreign material contamination, our medical-grade X-ray inspection technology and skilled labor force can get the job done like no other company can. We’re trusted by small, local businesses and household name brands.

Flexible Solutions

If you have a different quality control issue—whether it’s related to packaging, sealing, storage space or otherwise—FlexXray can still help. Our Flexible Solutions offer producers complete peace of mind in the quality of their product.

Industries We Serve

Protein

Beef, Poultry, Pork and Seafood

Dairy and Fluid Milk

Cheese, Butter, Ice Cream, Frozen Desserts and Fluid Milk

Fruits and Vegetables

Canned, Frozen and Liquified Fruits and Vegetables

Dry Food

Flour, Rice, Coffee, Tea, Spices and Powdered Supplements

Bakery

Bread, Cookies, Crackers, Snack Foods, Cereal, Frozen Cakes, Pies

Beverages

Breweries, Malt, Wineries, Liquor, Soft Drinks, Bottled Water, Flavoring Syrups

Consumer Packaged Goods

Frozen and Refrigerated Prepared Meals, Ready to Eat Foods

Confectionery

Candy, Chocolate and Gum Products

Pet Food

Dry or Canned Pet Food Products

Nutraceuticals

Vitamins, Supplements, Creatine, Protein Shakes and More

Non-Food Inspections

Cosmetics, Personal Care and Household Products

If you don’t see your industry on this list, don’t worry. Contact our team today, and together we’ll determine how our industry-leading capabilities can best serve your operations!